Share this

RTCA DO-160: Everything You Need to Know

by Brett Daniel on Jun 24, 2020 4:56:15 PM

Graphic: Do you need a DO-160-certified rugged server or workstation for your aerospace application? Are you interested in learning more about the standard? Worry not. We'll cover everything you need to know in this blog post.

Note: Trenton Systems is not a compliance testing facility. We manufacture rugged servers and workstations that conform to military and industrial standards, such as MIL-STD-810 and DO-160, and we can ensure that our systems comply with these standards using our in-house testing equipment, or by sending our systems to a third-party compliance testing laboratory for validation, but our facility does not offer compliance testing services for products manufactured outside of Trenton Systems. For a list of laboratories that can assist you with your testing needs, please read this blog post, which lists the best compliance testing laboratories in the world.

Where there’s a rugged server or workstation, there’s – hopefully - a compliance testing certification that accompanies it.

Whether it’s operating in the desert, in a submarine, or in the case of DO-160, in or on an aircraft, compliance certification by an in-house lab or compliance laboratory ensures that rugged servers endure and perform smoothly amid extreme conditions capable of rendering most computers inoperable.

There are many military and industrial testing standards used to ruggedize and stress-test servers for extreme conditions, two of the most common being MIL-STD-810 and DO-160.

DO-160 testing includes procedures for environments similar to those addressed in MIL-STD-810, such as high-humidity environments and high-vibration environments.

DO-160 tests, however, are tailored to assess rugged computers that are expected to operate in or on general aviation aircraft, helicopters, jumbo jets, or supersonic transports.

A DO-160-certified rugged server or workstation allows you to power your application in the air without worrying about damage or malfunctioning components, letting you and your team focus on what matters.

No matter what else happens, fly the airplane.

Graphic: RTCA / DO-160 has been used as an environmental testing standard for airborne equipment since as early as 1958, when it was known as DO-130.

DO-160 testing: What is it?

DO-160, officially titled Environmental Conditions and Test Procedures for Airborne Equipment, is a living document of environmental testing standards for airborne equipment. DO-160 is maintained and published by the Radio Technical Commission for Aeronautics or RTCA.

Although it isn’t a government standard or regulation, DO-160 has been adopted by the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) since its initial publication in 1975.

According to an advisory circular (AC) published by the FAA in June 2011, RTCA / DO-160 has been used as an environmental testing standard for airborne equipment since as early as 1958, when it was known as DO-130.

The latest revision of DO-160 – DO-160G – was published in December 2010 and includes updates for test conditions, power input, radio frequency susceptibility, among other changes.

DO-160 environmental testing isn’t a hard-and-fast requirement for equipment used in or on aircraft. It’s merely a standard; however, it has been adopted not only by government entities but by numerous equipment suppliers, airlines and compliance testing facilities to establish an industry-wide consensus on the quality and reliability of airborne equipment.

What test procedures are included in DO-160?

There are 23 test procedures in DO-160:

- Temperature and Altitude

- Temperature Variation

- Humidity

- Operational Shocks and Crash Safety

- Vibration

- Explosive Atmosphere

- Waterproofness

- Fluids Susceptibility

- Sand and Dust

- Fungus Resistance

- Salt Fog

- Magnetic Effect

- Power Input

- Voltage Spike

- Audio Frequency Conducted Susceptibility – Power Inputs

- Induced Signal Susceptibility

- Radio Frequency Susceptibility

- Radio Frequency Susceptibility (Radiated and Conducted)

- Emission of Radio Frequency Energy

- Lightning Induced Transient Susceptibility

- Lightning Direct Effects

- Icing

- Electrostatic Discharge

- Fire and Flammability

Each of the DO-160 sections is customer-specific and highly tailored to the eventual environment of the equipment or rugged computer system.

Trenton Systems has its own in-house DO-160 testing lab. We also partner with compliance testing labs that can accommodate additional DO-160 test procedures.

“At Trenton Systems, we typically perform shock, vibration, temperature, and humidity testing for DO-160 in-house. The ones we perform in-house are the most commonly requested. Typically, customers who have an avionics-type application or requirement request RTCA DO-160 testing. It’s per customer requirement, so we test roughly three to four times per year, based on what I’ve seen.”

-Gary Ziadeh, compliance coordinator at Trenton Systems

Some of our products that have undergone DO-160 testing include but are not limited to:

- The ION Rugged Mini PC

- 1U Rugged Servers and Processor Boards

- 5U Rugged Servers and Processor Boards

Contact Trenton Systems today to learn more about how we test for DO-160 temperature, humidity, shock and vibration standards, which we've chosen to highlight below.

RTCA DO-160 Section 4 - Temperature & Altitude

The purpose of DO-160 temperature and altitude testing is to assess the performance characteristics of equipment when exposed to extremely high or low temperatures and varying altitudes. This procedure includes 20 categories addressing the full range of environments known to exist in most aircraft types and installation locations.

Testing is performed by placing equipment into an environmental testing chamber, monitoring the effects on the equipment and recording results to determine pass or fail.

RTCA DO-160 Section 5 - Temperature Variation

The purpose of DO-160 temperature variation testing is to assess the performance characteristics of airborne equipment when exposed to sudden, extreme changes in temperature. This procedure includes five categories that address temperature change rates for equipment installed in or on aircraft.

As with DO-160 Section 4, testing is performed by placing equipment into an environmental testing chamber, monitoring the effects on the equipment and recording results to determine pass or fail.

RTCA DO-160 Section 6 – Humidity

The purpose of DO-160 humidity testing is to assess the ability of airborne equipment to endure exposure to natural or induced humidity, which can cause corrosion, altering of metals, conductors and insulators, and changes to the chemical properties of equipment.

RTCA / DO-160 Section 6 includes three equipment testing categories: Standard Humidity Environment (Category A), Severe Humidity Environment (Category B) and External Humidity Environment (Category C).

| DO-160 Humidity Environment Categories | ||

| Standard Humidity Environment | Severe Humidity Environment | External Humidity Environment |

| 48 hours of exposure | 240 hours of exposure | 144 hours of exposure |

| For equipment in civil aircraft & non-civil transport aircraft with environmental control | For equipment in aircraft environments with no environmental control | For equipment that comes into direct contact with outside air |

Table: A description of each of the categories specific to DO-160 humidity testing

DO-160’s Standard Humidity Environment category (Category A), which involves two cycles, or 48 hours of exposure, is intended for equipment installed in civil aircraft, non-civil transport aircraft and other classes. Primarily, it addresses any equipment within environmentally controlled compartments of aircraft in which the Severe Humidity Environment category (Category B) is not encountered.

DO-160’s Severe Humidity Environment (Category B) involves 10 cycles, or 240 hours of exposure, and is intended for equipment installed in an aircraft environment that is not environmentally controlled and exceeds the exposure time of the Standard Humidity Environment category (Category A).

DO-160’s External Humidity Environment category (Category C) involves six cycles, or 144 hours of exposure, and is intended for equipment that comes into direct contact with outside air for periods that exceed the Standard Humidity Environment category (Category A).

Testing is performed by placing equipment into an environmental testing chamber, monitoring the moisturizing effects that high humidity levels have on the equipment and recording the results to determine pass or fail.

Graph: The acceleration graph from a DO-160G shock test on Trenton Systems' ION Rugged Mini PC, which passed DO-160 testing with flying colors. This specific test was conducted in March 2020.

RTCA DO-160 Section 7 – Operational Shocks & Crash Safety

The purpose of DO-160 shock testing is to verify that equipment will continue to function within required performance standards after being exposed to shocks during normal aircraft operations.

“These shocks may occur during taxiing, landing or when the aircraft encounters sudden gusts in flight. This test applies to all equipment installed on fixed-wing aircraft and helicopters.”

- Excerpt from DO-160

DO-160 Section 7 also includes a crash safety test, which ensures that specific equipment doesn’t detach from its mountings or pose a hazard during an emergency landing.

“It applies to equipment installed in compartments and other areas of the aircraft where equipment detached during emergency landing could present a hazard to occupants, fuel systems or emergency evacuation equipment.”

- Excerpt from DO-160

DO-160 Section 7 includes four equipment testing categories: Standard Operational Shocks (Category A), Standard Operational Shock and Crash Safety (Category B), Low-Frequency Operational Shock (Category D) and Low-Frequency Crash Safety (Category E).

Testing is performed by strapping a piece of equipment to a shock table and using an accelerometer to measure and control shock pulses.

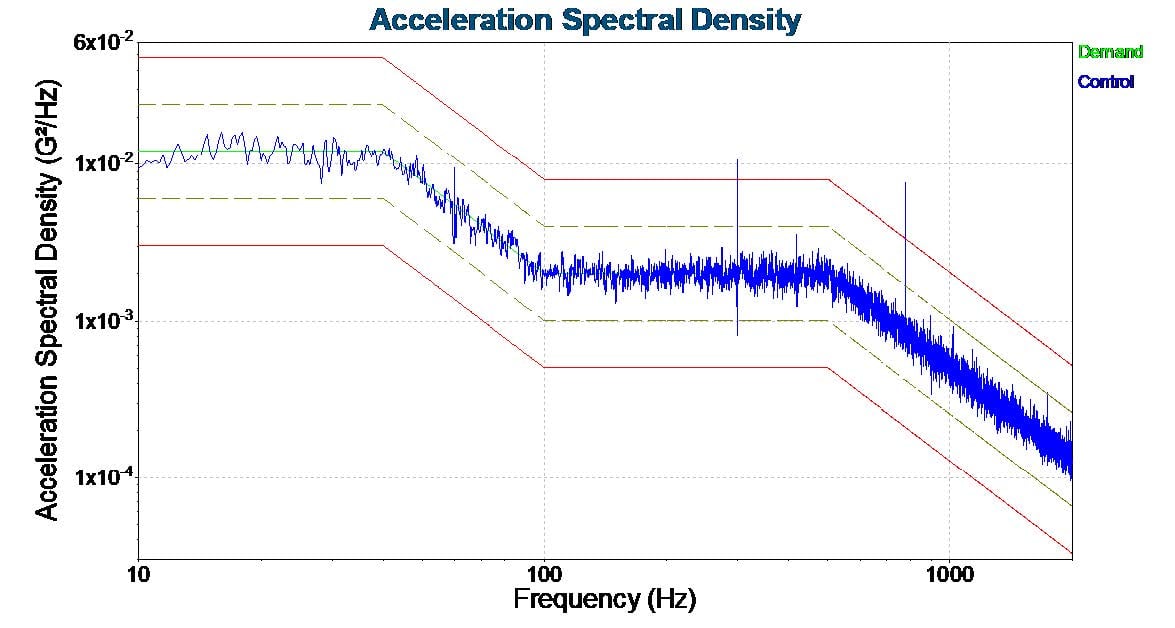

Graph: The acceleration spectral density graph from a DO-160G Y-axis vibration test conducted in March 2020 for the ION Mini PC

RTCA DO-160 Section 8 – Vibration

The purpose of DO-160 vibration testing, which involves a series of tests, is to demonstrate that airborne equipment complies with performance standards and durability requirements when subjected to installation-specific vibration levels.

| DO-160 Vibration Environment Categories | ||

| Standard Vibration Test | Robust Vibration Test | High-Level, Short-Duration Vibration Test |

| Can equipment meet its functional performance requirements in a typical vibration environment encountered during regular aircraft operation? | Can equipment operate as expected while being subjected to vibration and continue working after being subjected to endurance vibration levels? | Can equipment survive a loss of performance that could hazardously affect the performance of the aircraft? |

Table: A description of each of the tests specific to DO-160 vibration testing

There are three tests, each with one or more categories, associated with DO-160 vibration testing: Standard Vibration Test (Category S), Robust Vibration Test (Categories R, U, U2) and High-Level, Short-Duration Vibration Test (Categories H, Z).

The Standard Vibration Test (Category S) is for fixed-wing aircraft. It intends to determine whether the equipment will meet its functional performance requirements in a typical vibration environment encountered during regular aircraft operation.

The Robust Vibration Test (Categories R, U, U2) assesses whether the equipment will operate as expected while being subjected to vibration and continue working after being subjected to endurance vibration levels.

DO-160 describes the Robust Vibration Test as a combination assessment intended to observe the equipment’s functional performance and structural integrity.

The Robust Vibration Test is ideal for equipment exposed to vibration for long periods and includes testing procedures for equipment installed in helicopters as well.

The High-Level, Short-Duration Vibration Test is intended for vibration conditions that occur during an engine fan blade loss and should be applied to equipment in which loss of performance could hazardously affect the performance of the aircraft.

How does DO-160 compare to MIL-STD-810 & others?

Often, rugged servers are certified to DO-160, MIL-STD-461, MIL-STD-810, MIL-STD-704, and a cocktail of other military and industrial standards, but what exactly is the difference between all these standards, anyway?

DO-160 vs. MIL-STD-810

DO-160 test procedures are specifically tailored to assess the performance and durability characteristics of equipment intended to function and survive in challenging or extreme aircraft environments. It is used primarily by the aviation and aerospace industries.

MIL-STD-810, on the other hand, is a U.S. Department of Defense Standard used to test equipment that will ultimately be used by the U.S. Air Force, Army, Navy and other branches of the U.S. military. Unlike DO-160, MIL-STD-810 doesn’t focus on aircraft environments, specifically.

MIL-STD-810 does include a test for aircraft environments: Low Pressure (Altitude) or Method 500.6. This single procedure doesn’t mean that other MIL-STD-810 tests can’t be used for aircraft equipment testing. For example, MIL-STD-810 vibration testing can be applied to aircraft equipment.

Naturally, there is some overlap between the two standards, but there are environments and conditions exclusive to each standard as well. You won’t find, for example, tests for acidic atmosphere and solar radiation in DO-160. At the same time, you won’t find tests for the effects of lightning strikes in MIL-STD-810.

Testing overlap is a possibility considering that both standards test for similar conditions, e.g., salt fog, sand and dust, fungus and water or rain resistance. The main differences lie in the industry for which the testing is performed, the tailoring process and the technical consideration for the equipment’s real-world operational environment, e.g., in or on an aircraft, in a tank, in a submarine, in the desert, in the jungle, in the arctic and so on.

These standards are not only used to test equipment for usage in military and industrial programs and applications, however. MIL-STD-810 and DO-160 are often used to test equipment for commercial programs and applications as well.

DO-160 vs. MIL-STD-461

MIL-STD-461 is a DoD standard used to test the effectiveness of equipment in electromagnetic environments. In short, it assesses the overall electromagnetic compatibility of a piece of equipment or computer system.

Like with MIL-STD-810 and other U.S. military standards, MIL-STD-461 is primarily a requirement for equipment and computer systems used in military programs and applications.

The aerospace and aviation industries, and the test engineers or labs that perform the actual assessments, are more likely to refer to DO-160 for electromagnetic interference (EMI) requirements since the standard caters directly to aircraft equipment.

Like MIL-STD-461, there are sections in DO-160 for EMI testing, such as DO-160 Section 20 and DO-160 Section 21, which address the radio frequency interference (RFI) subtype specifically.

DO-160 vs. MIL-STD-704

MIL-STD-704 is essentially a collection of electric power specifications for military aircraft equipment.

MIL-STD-704 addresses military-grade electronic aircraft systems and conditions such as over- and under-voltage, over- and under-frequency, ripple voltage, electrical noise, among others. DO-160 has a similar section: DO-160 Section 16 – Power Input.

Like with other military standards, the purpose of MIL-STD-704 is to define DoD requirements for aircraft equipment used by the Army, Navy, Air Force and other military branches.

“The purpose of this interface standard is to ensure compatibility between the aircraft electric system, external power, and airborne utilization equipment.”

– Excerpt from DO-160

Naturally, commercial entities and other industries may also use MIL-STD-704 when testing aircraft equipment.

Conclusion

And there you have it: a comprehensive overview of RTCA DO-160.

We encourage you to download the full DO-160 PDF standard by purchasing a copy directly from the RTCA.

Do you need a rugged server or workstation certified to DO-160 testing standards? Trenton Systems can take care of that for you.

Share this

- High-performance computers (42)

- Military computers (38)

- Rugged computers (32)

- Cybersecurity (25)

- Industrial computers (25)

- Military servers (24)

- MIL-SPEC (20)

- Rugged servers (19)

- Press Release (17)

- Industrial servers (16)

- MIL-STD-810 (16)

- 5G Technology (14)

- Intel (13)

- Rack mount servers (12)

- processing (12)

- Computer hardware (11)

- Edge computing (11)

- Rugged workstations (11)

- Made in USA (10)

- Partnerships (9)

- Rugged computing (9)

- Sales, Marketing, and Business Development (9)

- Trenton Systems (9)

- networking (9)

- Peripheral Component Interconnect Express (PCIe) (7)

- Encryption (6)

- Federal Information Processing Standards (FIPS) (6)

- GPUs (6)

- IPU (6)

- Joint All-Domain Command and Control (JADC2) (6)

- Server motherboards (6)

- artificial intelligence (6)

- Computer stress tests (5)

- Cross domain solutions (5)

- Mission-critical servers (5)

- Rugged mini PCs (5)

- AI (4)

- BIOS (4)

- CPU (4)

- Defense (4)

- Military primes (4)

- Mission-critical systems (4)

- Platform Firmware Resilience (PFR) (4)

- Rugged blade servers (4)

- containerization (4)

- data protection (4)

- virtualization (4)

- Counterfeit electronic parts (3)

- DO-160 (3)

- Edge servers (3)

- Firmware (3)

- HPC (3)

- Just a Bunch of Disks (JBOD) (3)

- Leadership (3)

- Navy (3)

- O-RAN (3)

- RAID (3)

- RAM (3)

- Revision control (3)

- Ruggedization (3)

- SATCOM (3)

- Storage servers (3)

- Supply chain (3)

- Tactical Advanced Computer (TAC) (3)

- Wide-temp computers (3)

- computers made in the USA (3)

- data transfer (3)

- deep learning (3)

- embedded computers (3)

- embedded systems (3)

- firmware security (3)

- machine learning (3)

- Automatic test equipment (ATE) (2)

- C6ISR (2)

- COTS (2)

- COVID-19 (2)

- CPUs (2)

- Compliance (2)

- Compute Express Link (CXL) (2)

- Computer networking (2)

- Controlled Unclassified Information (CUI) (2)

- DDR (2)

- DDR4 (2)

- DPU (2)

- Dual CPU motherboards (2)

- EW (2)

- I/O (2)

- Military standards (2)

- NVIDIA (2)

- NVMe SSDs (2)

- PCIe (2)

- PCIe 4.0 (2)

- PCIe 5.0 (2)

- RAN (2)

- SIGINT (2)

- SWaP-C (2)

- Software Guard Extensions (SGX) (2)

- Submarines (2)

- Supply chain security (2)

- TAA compliance (2)

- airborne (2)

- as9100d (2)

- chassis (2)

- data diode (2)

- end-to-end solution (2)

- hardware security (2)

- hardware virtualization (2)

- integrated combat system (2)

- manufacturing reps (2)

- memory (2)

- mission computers (2)

- private 5G (2)

- protection (2)

- secure by design (2)

- small form factor (2)

- software security (2)

- vRAN (2)

- zero trust (2)

- zero trust architecture (2)

- 3U BAM Server (1)

- 4G (1)

- 4U (1)

- 5G Frequencies (1)

- 5G Frequency Bands (1)

- AI/ML/DL (1)

- Access CDS (1)

- Aegis Combat System (1)

- Armed Forces (1)

- Asymmetric encryption (1)

- C-RAN (1)

- COMINT (1)

- Cloud-based CDS (1)

- Coast Guard (1)

- Compliance testing (1)

- Computer life cycle (1)

- Containers (1)

- D-RAN (1)

- DART (1)

- DDR5 (1)

- DMEA (1)

- Data Center Modular Hardware System (DC-MHS) (1)

- Data Plane Development Kit (DPDK) (1)

- Defense Advanced Research Projects (DARP) (1)

- ELINT (1)

- EMI (1)

- EO/IR (1)

- Electromagnetic Interference (1)

- Electronic Warfare (EW) (1)

- FIPS 140-2 (1)

- FIPS 140-3 (1)

- Field Programmable Gate Array (FPGA) (1)

- Ground Control Stations (GCS) (1)

- Hardware-based CDS (1)

- Hybrid CDS (1)

- IES.5G (1)

- ION Mini PC (1)

- IP Ratings (1)

- IPMI (1)

- Industrial Internet of Things (IIoT) (1)

- Industry news (1)

- Integrated Base Defense (IBD) (1)

- LAN ports (1)

- LTE (1)

- Life cycle management (1)

- Lockheed Martin (1)

- MIL-S-901 (1)

- MIL-STD-167-1 (1)

- MIL-STD-461 (1)

- MIL-STD-464 (1)

- MOSA (1)

- Multi-Access Edge Computing (1)

- NASA (1)

- NIC (1)

- NIC Card (1)

- NVMe (1)

- O-RAN compliant (1)

- Oil and Gas (1)

- Open Compute Project (OCP) (1)

- OpenRAN (1)

- P4 (1)

- PCIe card (1)

- PCIe lane (1)

- PCIe slot (1)

- Precision timestamping (1)

- Product life cycle (1)

- ROM (1)

- Raytheon (1)

- Remotely piloted aircraft (RPA) (1)

- Rugged computing glossary (1)

- SEDs (1)

- SIM Card (1)

- Secure boot (1)

- Sensor Open Systems Architecture (SOSA) (1)

- Small form-factor pluggable (SFP) (1)

- Smart Edge (1)

- Smart NIC (1)

- SmartNIC (1)

- Software-based CDS (1)

- Symmetric encryption (1)

- System hardening (1)

- System hardening best practices (1)

- TME (1)

- Tech Partners (1)

- Total Memory Encryption (TME) (1)

- Transfer CDS (1)

- USB ports (1)

- VMEbus International Trade Association (VITA) (1)

- Vertical Lift Consortium (VLC) (1)

- Virtual machines (1)

- What are embedded systems? (1)

- Wired access backhaul (1)

- Wireless access backhaul (1)

- accredidation (1)

- aerospace (1)

- air gaps (1)

- airborne computers (1)

- asteroid (1)

- authentication (1)

- autonomous (1)

- certification (1)

- cognitive software-defined radios (CDRS) (1)

- command and control (C2) (1)

- communications (1)

- cores (1)

- custom (1)

- customer service (1)

- customer support (1)

- data linking (1)

- data recording (1)

- ethernet (1)

- full disk encryption (1)

- hardware monitoring (1)

- heat sink (1)

- hypervisor (1)

- in-house technical support (1)

- input (1)

- integrated edge solution (1)

- international business (1)

- licensed spectrum (1)

- liquid cooling (1)

- mCOTS (1)

- microelectronics (1)

- missile defense (1)

- mixed criticality (1)

- moving (1)

- multi-factor authentication (1)

- network slicing (1)

- neural networks (1)

- new headquarters (1)

- next generation interceptor (1)

- non-volatile memory (1)

- operating system (1)

- output (1)

- outsourced technical support (1)

- post-boot (1)

- pre-boot (1)

- private networks (1)

- public networks (1)

- radio access network (RAN) (1)

- reconnaissance (1)

- rugged memory (1)

- secure flash (1)

- security (1)

- self-encrypting drives (SEDs) (1)

- sff (1)

- software (1)

- software-defined radios (SDRs) (1)

- speeds and feeds (1)

- standalone (1)

- storage (1)

- systems (1)

- tactical wide area networks (1)

- technical support (1)

- technology (1)

- third-party motherboards (1)

- troposcatter communication (1)

- unlicensed spectrum (1)

- volatile memory (1)

- vpx (1)

- zero trust network (1)

- January 2025 (1)

- November 2024 (1)

- October 2024 (1)

- August 2024 (1)

- July 2024 (1)

- May 2024 (1)

- April 2024 (3)

- February 2024 (1)

- November 2023 (1)

- October 2023 (1)

- July 2023 (1)

- June 2023 (3)

- May 2023 (7)

- April 2023 (5)

- March 2023 (7)

- December 2022 (2)

- November 2022 (6)

- October 2022 (7)

- September 2022 (8)

- August 2022 (3)

- July 2022 (4)

- June 2022 (13)

- May 2022 (10)

- April 2022 (4)

- March 2022 (11)

- February 2022 (4)

- January 2022 (4)

- December 2021 (1)

- November 2021 (4)

- September 2021 (2)

- August 2021 (1)

- July 2021 (2)

- June 2021 (3)

- May 2021 (4)

- April 2021 (3)

- March 2021 (3)

- February 2021 (8)

- January 2021 (4)

- December 2020 (5)

- November 2020 (5)

- October 2020 (4)

- September 2020 (4)

- August 2020 (6)

- July 2020 (9)

- June 2020 (11)

- May 2020 (13)

- April 2020 (8)

- February 2020 (1)

- January 2020 (1)

- October 2019 (1)

- August 2019 (2)

- July 2019 (2)

- March 2019 (1)

- January 2019 (2)

- December 2018 (1)

- November 2018 (2)

- October 2018 (5)

- September 2018 (3)

- July 2018 (1)

- April 2018 (2)

- March 2018 (1)

- February 2018 (9)

- January 2018 (27)

- December 2017 (1)

- November 2017 (2)

- October 2017 (3)

/Trenton%20Systems%20Circular%20Logo-3.png?width=50&height=50&name=Trenton%20Systems%20Circular%20Logo-3.png)

Comments (2)