Share this

How Revision Control Secures Your Computer

by Jason Barr on Feb 19, 2021 3:29:23 PM

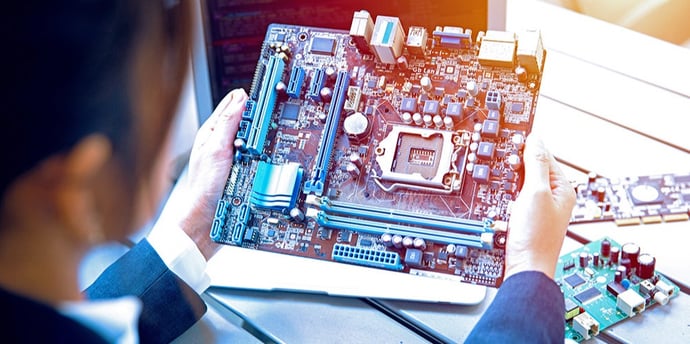

Photo: Working with a computer hardware manufacturer with a strict revision control system in place is an essential aspect of further securing your cybersecure computing solution.

Table of Contents

- Suppliers get added to an approved vendor list (AVL).

- How does a part get approved and added to a computer?

- What happens if a hardware change is required?

The fact that Trenton Systems designs its own processor boards in Atlanta, Georgia, allows the company to have control of the hardware down to the minutiae, from the resistors all the way up to the CPU.

Trenton’s computers must be the same form, fit, and function over the life of the product, and we average over 11 years of availability compared to three years from our competitors.

Maintaining hardware revision control is no easy task for products that can consist of thousands of discrete parts, but a long-life, revision-controlled processor board is ideal for embedded military applications that cannot change over the life of the program.

And because every revision control system is different, we've decided to focus on our own for the purposes of this blog post.

Trenton has a 31-year proven history of developing and manufacturing high-performance computers and ensuring consistent revision control, and this blog post will highlight some of those required processes and procedures.

Photo: Maintaining and frequently reviewing approved vendor lists (AVL) helps computer hardware manufacturers ensure a secure supply chain.

Suppliers get added to an approved vendor list (AVL)

Trenton maintains a revision-controlled Approved Vendor List (AVL) that consists of thousands of parts. The AVL documents the primary part and alternate parts that may be used for life cycle changes or availability concerns related to the primary part.

Each part is approved by the engineers that designed the products. This AVL is monitored to ensure that approved components are currently available and identify when additional alternates may be necessary.

Doing so helps maintain a robust and secure supply chain because it enables the manufacturer to make investment purchases of components nearing the end of their life cycle or identify alternates proactively, rather than scrambling in an attempt to find end-of-life (EOL) or supply-constrained components. In addition, each processor board has a unique bill of material (BOM) that is also revision-controlled.

Photo: Form, fit, function, and regulation verification is a necessary aspect of part approval and incorporation.

But how does a part get approved and added to a board?

Trenton's design engineers have a part notification process that verifies whether the part - for instance, a capacitor or voltage regulator - meets the necessary form, fit, function, and regulatory requirements. That part notification also gets approved by purchasing - for cost & availability from authorized supply chain channels - production - for manufacturability and inventory reviews - and quality control - for numerous regulatory and quality regulation reviews.

Trenton also controls the manufacturing process - for instance, SMT and AOI requirements - throughout the entire supply chain. This ensures that Trenton controls the full supply chain and that no malicious or counterfeit electronic parts are introduced.

Note that Trenton also controls the firmware design - BIOS, IPMI, fan control, and other features - programmed into the processor board. Trenton also does the final assembly - power supply, hard drives, etc. - at its secure facility in Atlanta through a very similar revision control process.

Photo: If a hardware change is required, a similar but different part may be used to ensure your computer keeps functioning as intended.

So, what happens if a hardware change is required?

There are occasions where a hardware change must happen - for instance, when a subcomponent goes obsolete, and there is no drop-in form, fit, and function replacement.

If a design change is required, then Trenton engineering can redesign with a similar but different part. Note that any change that is not a form, fit, or function replacement has a product information notice (PIN) sales process for notifying customers of any pending change, cut-in dates, and that provides a summary of why the change is required.

If and when form, fit, or function changes occur, the board is issued a new revision through our Engineering Change Order (ECO) process. The ECO process requires approval from stakeholders within the company, provides full documentation of changes for future reference, and requires the revised processor to be labeled with the new revision.

The combination of a product revision control system, our part creation process, and supply chain monitoring enables Trenton Systems to maintain a secure supply chain that protects your products from counterfeit parts, obsolescence, and nefarious hardware hacking attempts.

For more information on how we secure our supply chain and protect your high-performance computer, don't hesitate to reach out. We're here for you.

Share this

- High-performance computers (42)

- Military computers (38)

- Rugged computers (32)

- Cybersecurity (25)

- Industrial computers (25)

- Military servers (24)

- MIL-SPEC (20)

- Rugged servers (19)

- Press Release (17)

- Industrial servers (16)

- MIL-STD-810 (16)

- 5G Technology (14)

- Intel (13)

- Rack mount servers (12)

- processing (12)

- Computer hardware (11)

- Edge computing (11)

- Rugged workstations (11)

- Made in USA (10)

- Partnerships (9)

- Rugged computing (9)

- Sales, Marketing, and Business Development (9)

- Trenton Systems (9)

- networking (9)

- Peripheral Component Interconnect Express (PCIe) (7)

- Encryption (6)

- Federal Information Processing Standards (FIPS) (6)

- GPUs (6)

- IPU (6)

- Joint All-Domain Command and Control (JADC2) (6)

- Server motherboards (6)

- artificial intelligence (6)

- Computer stress tests (5)

- Cross domain solutions (5)

- Mission-critical servers (5)

- Rugged mini PCs (5)

- AI (4)

- BIOS (4)

- CPU (4)

- Defense (4)

- Military primes (4)

- Mission-critical systems (4)

- Platform Firmware Resilience (PFR) (4)

- Rugged blade servers (4)

- containerization (4)

- data protection (4)

- virtualization (4)

- Counterfeit electronic parts (3)

- DO-160 (3)

- Edge servers (3)

- Firmware (3)

- HPC (3)

- Just a Bunch of Disks (JBOD) (3)

- Leadership (3)

- Navy (3)

- O-RAN (3)

- RAID (3)

- RAM (3)

- Revision control (3)

- Ruggedization (3)

- SATCOM (3)

- Storage servers (3)

- Supply chain (3)

- Tactical Advanced Computer (TAC) (3)

- Wide-temp computers (3)

- computers made in the USA (3)

- data transfer (3)

- deep learning (3)

- embedded computers (3)

- embedded systems (3)

- firmware security (3)

- machine learning (3)

- Automatic test equipment (ATE) (2)

- C6ISR (2)

- COTS (2)

- COVID-19 (2)

- CPUs (2)

- Compliance (2)

- Compute Express Link (CXL) (2)

- Computer networking (2)

- Controlled Unclassified Information (CUI) (2)

- DDR (2)

- DDR4 (2)

- DPU (2)

- Dual CPU motherboards (2)

- EW (2)

- I/O (2)

- Military standards (2)

- NVIDIA (2)

- NVMe SSDs (2)

- PCIe (2)

- PCIe 4.0 (2)

- PCIe 5.0 (2)

- RAN (2)

- SIGINT (2)

- SWaP-C (2)

- Software Guard Extensions (SGX) (2)

- Submarines (2)

- Supply chain security (2)

- TAA compliance (2)

- airborne (2)

- as9100d (2)

- chassis (2)

- data diode (2)

- end-to-end solution (2)

- hardware security (2)

- hardware virtualization (2)

- integrated combat system (2)

- manufacturing reps (2)

- memory (2)

- mission computers (2)

- private 5G (2)

- protection (2)

- secure by design (2)

- small form factor (2)

- software security (2)

- vRAN (2)

- zero trust (2)

- zero trust architecture (2)

- 3U BAM Server (1)

- 4G (1)

- 4U (1)

- 5G Frequencies (1)

- 5G Frequency Bands (1)

- AI/ML/DL (1)

- Access CDS (1)

- Aegis Combat System (1)

- Armed Forces (1)

- Asymmetric encryption (1)

- C-RAN (1)

- COMINT (1)

- Cloud-based CDS (1)

- Coast Guard (1)

- Compliance testing (1)

- Computer life cycle (1)

- Containers (1)

- D-RAN (1)

- DART (1)

- DDR5 (1)

- DMEA (1)

- Data Center Modular Hardware System (DC-MHS) (1)

- Data Plane Development Kit (DPDK) (1)

- Defense Advanced Research Projects (DARP) (1)

- ELINT (1)

- EMI (1)

- EO/IR (1)

- Electromagnetic Interference (1)

- Electronic Warfare (EW) (1)

- FIPS 140-2 (1)

- FIPS 140-3 (1)

- Field Programmable Gate Array (FPGA) (1)

- Ground Control Stations (GCS) (1)

- Hardware-based CDS (1)

- Hybrid CDS (1)

- IES.5G (1)

- ION Mini PC (1)

- IP Ratings (1)

- IPMI (1)

- Industrial Internet of Things (IIoT) (1)

- Industry news (1)

- Integrated Base Defense (IBD) (1)

- LAN ports (1)

- LTE (1)

- Life cycle management (1)

- Lockheed Martin (1)

- MIL-S-901 (1)

- MIL-STD-167-1 (1)

- MIL-STD-461 (1)

- MIL-STD-464 (1)

- MOSA (1)

- Multi-Access Edge Computing (1)

- NASA (1)

- NIC (1)

- NIC Card (1)

- NVMe (1)

- O-RAN compliant (1)

- Oil and Gas (1)

- Open Compute Project (OCP) (1)

- OpenRAN (1)

- P4 (1)

- PCIe card (1)

- PCIe lane (1)

- PCIe slot (1)

- Precision timestamping (1)

- Product life cycle (1)

- ROM (1)

- Raytheon (1)

- Remotely piloted aircraft (RPA) (1)

- Rugged computing glossary (1)

- SEDs (1)

- SIM Card (1)

- Secure boot (1)

- Sensor Open Systems Architecture (SOSA) (1)

- Small form-factor pluggable (SFP) (1)

- Smart Edge (1)

- Smart NIC (1)

- SmartNIC (1)

- Software-based CDS (1)

- Symmetric encryption (1)

- System hardening (1)

- System hardening best practices (1)

- TME (1)

- Tech Partners (1)

- Total Memory Encryption (TME) (1)

- Transfer CDS (1)

- USB ports (1)

- VMEbus International Trade Association (VITA) (1)

- Vertical Lift Consortium (VLC) (1)

- Virtual machines (1)

- What are embedded systems? (1)

- Wired access backhaul (1)

- Wireless access backhaul (1)

- accredidation (1)

- aerospace (1)

- air gaps (1)

- airborne computers (1)

- asteroid (1)

- authentication (1)

- autonomous (1)

- certification (1)

- cognitive software-defined radios (CDRS) (1)

- command and control (C2) (1)

- communications (1)

- cores (1)

- custom (1)

- customer service (1)

- customer support (1)

- data linking (1)

- data recording (1)

- ethernet (1)

- full disk encryption (1)

- hardware monitoring (1)

- heat sink (1)

- hypervisor (1)

- in-house technical support (1)

- input (1)

- integrated edge solution (1)

- international business (1)

- licensed spectrum (1)

- liquid cooling (1)

- mCOTS (1)

- microelectronics (1)

- missile defense (1)

- mixed criticality (1)

- moving (1)

- multi-factor authentication (1)

- network slicing (1)

- neural networks (1)

- new headquarters (1)

- next generation interceptor (1)

- non-volatile memory (1)

- operating system (1)

- output (1)

- outsourced technical support (1)

- post-boot (1)

- pre-boot (1)

- private networks (1)

- public networks (1)

- radio access network (RAN) (1)

- reconnaissance (1)

- rugged memory (1)

- secure flash (1)

- security (1)

- self-encrypting drives (SEDs) (1)

- sff (1)

- software (1)

- software-defined radios (SDRs) (1)

- speeds and feeds (1)

- standalone (1)

- storage (1)

- systems (1)

- tactical wide area networks (1)

- technical support (1)

- technology (1)

- third-party motherboards (1)

- troposcatter communication (1)

- unlicensed spectrum (1)

- volatile memory (1)

- vpx (1)

- zero trust network (1)

- January 2025 (1)

- November 2024 (1)

- October 2024 (1)

- August 2024 (1)

- July 2024 (1)

- May 2024 (1)

- April 2024 (3)

- February 2024 (1)

- November 2023 (1)

- October 2023 (1)

- July 2023 (1)

- June 2023 (3)

- May 2023 (7)

- April 2023 (5)

- March 2023 (7)

- December 2022 (2)

- November 2022 (6)

- October 2022 (7)

- September 2022 (8)

- August 2022 (3)

- July 2022 (4)

- June 2022 (13)

- May 2022 (10)

- April 2022 (4)

- March 2022 (11)

- February 2022 (4)

- January 2022 (4)

- December 2021 (1)

- November 2021 (4)

- September 2021 (2)

- August 2021 (1)

- July 2021 (2)

- June 2021 (3)

- May 2021 (4)

- April 2021 (3)

- March 2021 (3)

- February 2021 (8)

- January 2021 (4)

- December 2020 (5)

- November 2020 (5)

- October 2020 (4)

- September 2020 (4)

- August 2020 (6)

- July 2020 (9)

- June 2020 (11)

- May 2020 (13)

- April 2020 (8)

- February 2020 (1)

- January 2020 (1)

- October 2019 (1)

- August 2019 (2)

- July 2019 (2)

- March 2019 (1)

- January 2019 (2)

- December 2018 (1)

- November 2018 (2)

- October 2018 (5)

- September 2018 (3)

- July 2018 (1)

- April 2018 (2)

- March 2018 (1)

- February 2018 (9)

- January 2018 (27)

- December 2017 (1)

- November 2017 (2)

- October 2017 (3)

/Trenton%20Systems%20Circular%20Logo-3.png?width=50&height=50&name=Trenton%20Systems%20Circular%20Logo-3.png)

No Comments Yet

Let us know what you think