Share this

MIL-STD-810 Shock Testing Overview [Method 516.8]

by Brett Daniel on May 26, 2020 9:32:33 AM

-3.png?width=1000&name=Untitled%20design%20(11)-3.png)

Graphic: MIL-STD-810 shock testing, also known as Test Method 516.8, is arguably one of the most well-known methods in MIL-STD-810.

Note: Trenton Systems is not a compliance testing facility. We manufacture rugged servers and workstations that conform to military and industrial standards, such as MIL-STD-810 and DO-160, and we can ensure that our systems comply with these standards using our in-house testing equipment, or by sending our systems to a third-party compliance testing laboratory for validation, but our facility does not offer compliance testing services for products manufactured outside of Trenton Systems. For a list of laboratories that can assist you with your testing needs, please read this blog post, which lists the best compliance testing laboratories in the world.

This is Part 4 in a series of the different test methods in MIL-STD-810H, the successor to MIL-STD-810G. View Part 3: Sand and Dust Testing and Part 2: Vibration Testing.

Buckle up, friends. You're in for a shocker.

MIL-STD-810 shock testing - also known as Test Method 516.8 - is arguably the most well-known method in the entire 1,000-page document due to its widespread use in product drop testing.

Whether your rugged computer is installed in an aircraft or being transported in a ground vehicle, there's a chance it will endure mechanical shock at some point during its life cycle.

-3.png?width=1000&name=Untitled%20design%20(12)-3.png)

Graphic: MIL-STD-810 shock testing assesses the effects of mechanical shock impact on a system.

What is MIL-STD-810 shock testing?

The purpose of MIL-STD-810 shock testing, or Method 516.8, is to assess a system’s resilience to physical impact in handling, transportation and service environments, according to the standard’s latest revision.

In the context of MIL-STD-810, shock refers to mechanical, rather than electric, shock.

A MIL-STD-810 shock test, therefore, assesses the structural and functional effects of mechanical shock impact on a system.

Shock testing also assesses a system’s fragility level. This ultimately helps with creating protective packaging, stowage and mounting configurations, which ensures the system’s physical and functional integrity.

In addition, shock testing is used to assess the strength of devices that are at risk of being involved in a crash and experiencing breakage or ejection as a result.

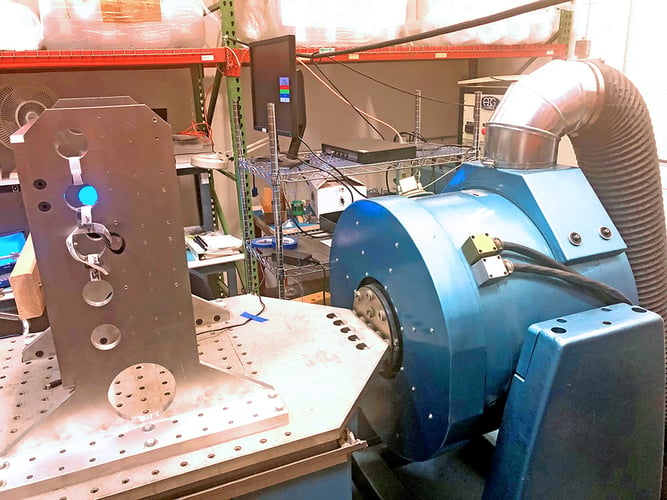

Photo: Trenton Systems' in-house shock and vibe testing table

How is a shock test performed?

A mechanical shock test is performed using special shock testing equipment, such as a shock table. Typically, a system is exposed to sudden, forceful accelerations and decelerations for less than one second.

We at Trenton Systems perform mechanical shock testing using our in-house shock and vibe testing table. Using the shock testing methods specified in MIL-STD-810, we further enhance the ruggedization of our servers and workstations by markedly improving their resistance to impact in the field.

We perform shock testing roughly 3-5 times per year.

Our shock testing is typically driven by a customer requirement. These tests are designed to control parameters such as pulse shape, peak acceleration and duration per the test method. Most of this testing is handled via our software-controlled shock and vibration table."

- Gary Ziadeh, compliance coordinator at Trenton Systems

Shock testing is usually requested because of the destructive effects that sudden physical impact can have on a system, including:

- Failure as a result of increased or decreased friction between parts, or general interference between parts

- Changes in dielectric strength, loss of insulation resistance and variations in magnetic and electrostatic field strength

- Electronic circuit card malfunction, electronic circuit card damage and electronic connector failure

- Permanent mechanical deformation as a result of overstress of structural and non-structural members

- Collapse of mechanical elements as a result of the ultimate strength of the component being exceeded

- Accelerated fatiguing of materials

- Potential piezoelectric activity of materials

- Failure as a result of cracks in fracturing crystals, ceramics, epoxies or glass envelopes

What are the different shock testing methods?

There are eight different MIL-STD-810 shock testing methods or procedures:

- Procedure I – Functional Shock

- Procedure II – Transportation Shock

- Procedure III – Fragility

- Procedure IV – Transit Drop

- Procedure V – Crash Hazard Shock Test

- Procedure VI – Bench Handling

- Procedure VII – Pendulum Impact

- Procedure VIII – Catapult Launch / Arrested Landing

| Procedure | Description | Packaged | Unpackaged | Operational | Non-Operational |

| I | Functional Shock | X | X | ||

| II | Transportation Shock | X | X | X | |

| III | Fragility | X | X | ||

| IV | Transit Drop | X | X | X | |

| V | Crash Hazard Shock | X | |||

| VI | Bench Handling | X | X | ||

| VII | Pendulum Impact | X | X | ||

| VIII | Catapult Launch / Arrested Landing | X | X |

Table: The different procedures in Method 516.8 and the state of the system or material during testing, as depicted in MIL-STD-810H

Procedure I – Functional Shock

Procedure I – Functional Shock assesses the overall survivability of a system and observes whether any functional damage from shocks occurs during system operation.

The shocks administered during this procedure are designed to represent those encountered in operational service environments.

Procedure II – Transportation Shock

Procedure II – Transportation Shock assesses the response of a system to the repetitive shocks encountered in certain transit environments, such as during ground vehicle transportation.

A classical terminal peak sawtooth shock is used. Repetitive shocks may be of similar or varying amplitude and frequency bandwidth.

It’s important to note that MIL-STD-810 does not consider this procedure an equivalent to secured and loose cargo vibration testing in Method 514.18.

Procedure III – Fragility

Procedure III – Fragility basically assesses the strength and frangibility of a system.

Fragility testing is also used to determine the right packaging, stowage or mounting configurations, as well as what specific shock conditions will cause structural or operational damage to the system.

During this procedure, shocks are essentially increased in magnitude until damage or impairment occurs.

Procedure IV – Transit Drop

When you see blogs and other publications mention MIL-STD-810 drop test standards or military drop test standards, they’re referring to Procedure IV – Transit Drop in Method 516.8 of MIL-STD-810.

The procedure involves placing a system is placed inside its transit case, or not, and dropping it onto a hard surface.

The procedure is used to determine if a system is capable of withstanding accidental drops during loading and unloading, such as when it’s being removed from a server rack.

Procedure V – Crash Hazard Shock

Procedure V – Crash Hazard Shock Test assesses systems mounted in air or ground vehicles that could become detached during a crash and present a hazard to drivers, pilots, passengers or bystanders.

This procedure uses simulated crashes to verify the overall structural integrity of a system, as well as any mounts, tie-downs or containment configurations.

Procedure VI – Bench Handling

Procedure VI – Bench Handling is for systems that may experience shock on a work bench during maintenance, repair or packaging.

The test is performed with the system outside of its transit case or packaging.

Procedure VII – Pendulum Impact

Procedure VI – Pendulum Impact assesses the ability of large shipping containers to resist shock resulting from horizontal impact, in addition to how effective packaging and packing methods for the container’s contents are in terms of overall protection.

The test is intended to simulate accidental impacts and is used only on susceptible containers – those that are large, heavy and likely to be handled mechanically as opposed to manually.

Procedure VIII – Catapult Launch / Arrested Landing

Procedure VIII – Catapult Launch / Arrested Landing is for systems or material mounted on or in fixed-wing aircraft that is subject to shock from catapult launches and arrested landings.

Aircraft catapult launches and the rapid deceleration associated with arrested landings are commonly performed on aircraft carriers.

| Test Category | Peak Acceleration (G-Pk) |

| Functional Test for Flight Equipment | 20 |

| Functional Test for Ground Equipment | 40 |

| Launch / Eject During Captive Carry | 30 |

| Crash Hazard Shock Test for Flight Equipment | 40 |

| Crash Hazard Shock Test for Ground Equipment | 75 |

Table: The peak accelerations for flight and ground equipment relative to functional, launch / eject and crash hazard shock test categories, as depicted in MIL-STD-810H

How is mechanical shock measured?

Mechanical shock pulses are measured in Gs, which is just a unit of measurement for gravity acceleration.

The longer the shock pulse lasts and the higher the number of Gs, the more damage that is done to the system. This is why systems are impacted in mere milliseconds during testing.

What is the difference between shock and vibration testing?

Certain shock and vibration testing standards may seem identical or even substitutable, but overall, the two test methods are quite different.

Shock testing measures physical or mechanical shock or impact using drop or direct collision assessments. Systems may be mechanically released from a certain height or subjected to a series of shocks in place using shock testing equipment.

Vibration testing, on the other hand, simulates the consistent shaking and juddering a system experiences throughout different stages of its life cycle, such as during transportation and operation.

Check out Part 2 of this series to learn more about MIL-STD-810 vibration testing.

-2.png?width=1000&name=Untitled%20design%20(13)-2.png)

Graphic: If there's even the slightest chance that your rugged server or workstation could experience mechanical shock during its lifetime, MIL-STD-810 shock testing might be worth asking about.

Should you ask about shock testing for your rugged computer?

If your system is predicted to endure any type or level of mechanical shock at any point during its life cycle, then we recommend asking your rugged computer manufacturer about MIL-STD-810 shock testing.

Using our software-controlled shock testing equipment, our talented test engineers can easily conduct and tailor this quick assessment to the most common procedures listed in the method.

And if for some reason we can’t perform the specific shock test you’re interested in, we partner with local testing labs that can get the job done.

Share this

- High-performance computers (42)

- Military computers (38)

- Rugged computers (32)

- Cybersecurity (25)

- Industrial computers (25)

- Military servers (24)

- MIL-SPEC (20)

- Rugged servers (19)

- Press Release (17)

- Industrial servers (16)

- MIL-STD-810 (16)

- 5G Technology (14)

- Intel (13)

- Rack mount servers (12)

- processing (12)

- Computer hardware (11)

- Edge computing (11)

- Rugged workstations (11)

- Made in USA (10)

- Partnerships (9)

- Rugged computing (9)

- Sales, Marketing, and Business Development (9)

- Trenton Systems (9)

- networking (9)

- Peripheral Component Interconnect Express (PCIe) (7)

- Encryption (6)

- Federal Information Processing Standards (FIPS) (6)

- GPUs (6)

- IPU (6)

- Joint All-Domain Command and Control (JADC2) (6)

- Server motherboards (6)

- artificial intelligence (6)

- Computer stress tests (5)

- Cross domain solutions (5)

- Mission-critical servers (5)

- Rugged mini PCs (5)

- AI (4)

- BIOS (4)

- CPU (4)

- Defense (4)

- Military primes (4)

- Mission-critical systems (4)

- Platform Firmware Resilience (PFR) (4)

- Rugged blade servers (4)

- containerization (4)

- data protection (4)

- virtualization (4)

- Counterfeit electronic parts (3)

- DO-160 (3)

- Edge servers (3)

- Firmware (3)

- HPC (3)

- Just a Bunch of Disks (JBOD) (3)

- Leadership (3)

- Navy (3)

- O-RAN (3)

- RAID (3)

- RAM (3)

- Revision control (3)

- Ruggedization (3)

- SATCOM (3)

- Storage servers (3)

- Supply chain (3)

- Tactical Advanced Computer (TAC) (3)

- Wide-temp computers (3)

- computers made in the USA (3)

- data transfer (3)

- deep learning (3)

- embedded computers (3)

- embedded systems (3)

- firmware security (3)

- machine learning (3)

- Automatic test equipment (ATE) (2)

- C6ISR (2)

- COTS (2)

- COVID-19 (2)

- CPUs (2)

- Compliance (2)

- Compute Express Link (CXL) (2)

- Computer networking (2)

- Controlled Unclassified Information (CUI) (2)

- DDR (2)

- DDR4 (2)

- DPU (2)

- Dual CPU motherboards (2)

- EW (2)

- I/O (2)

- Military standards (2)

- NVIDIA (2)

- NVMe SSDs (2)

- PCIe (2)

- PCIe 4.0 (2)

- PCIe 5.0 (2)

- RAN (2)

- SIGINT (2)

- SWaP-C (2)

- Software Guard Extensions (SGX) (2)

- Submarines (2)

- Supply chain security (2)

- TAA compliance (2)

- airborne (2)

- as9100d (2)

- chassis (2)

- data diode (2)

- end-to-end solution (2)

- hardware security (2)

- hardware virtualization (2)

- integrated combat system (2)

- manufacturing reps (2)

- memory (2)

- mission computers (2)

- private 5G (2)

- protection (2)

- secure by design (2)

- small form factor (2)

- software security (2)

- vRAN (2)

- zero trust (2)

- zero trust architecture (2)

- 3U BAM Server (1)

- 4G (1)

- 4U (1)

- 5G Frequencies (1)

- 5G Frequency Bands (1)

- AI/ML/DL (1)

- Access CDS (1)

- Aegis Combat System (1)

- Armed Forces (1)

- Asymmetric encryption (1)

- C-RAN (1)

- COMINT (1)

- Cloud-based CDS (1)

- Coast Guard (1)

- Compliance testing (1)

- Computer life cycle (1)

- Containers (1)

- D-RAN (1)

- DART (1)

- DDR5 (1)

- DMEA (1)

- Data Center Modular Hardware System (DC-MHS) (1)

- Data Plane Development Kit (DPDK) (1)

- Defense Advanced Research Projects (DARP) (1)

- ELINT (1)

- EMI (1)

- EO/IR (1)

- Electromagnetic Interference (1)

- Electronic Warfare (EW) (1)

- FIPS 140-2 (1)

- FIPS 140-3 (1)

- Field Programmable Gate Array (FPGA) (1)

- Ground Control Stations (GCS) (1)

- Hardware-based CDS (1)

- Hybrid CDS (1)

- IES.5G (1)

- ION Mini PC (1)

- IP Ratings (1)

- IPMI (1)

- Industrial Internet of Things (IIoT) (1)

- Industry news (1)

- Integrated Base Defense (IBD) (1)

- LAN ports (1)

- LTE (1)

- Life cycle management (1)

- Lockheed Martin (1)

- MIL-S-901 (1)

- MIL-STD-167-1 (1)

- MIL-STD-461 (1)

- MIL-STD-464 (1)

- MOSA (1)

- Multi-Access Edge Computing (1)

- NASA (1)

- NIC (1)

- NIC Card (1)

- NVMe (1)

- O-RAN compliant (1)

- Oil and Gas (1)

- Open Compute Project (OCP) (1)

- OpenRAN (1)

- P4 (1)

- PCIe card (1)

- PCIe lane (1)

- PCIe slot (1)

- Precision timestamping (1)

- Product life cycle (1)

- ROM (1)

- Raytheon (1)

- Remotely piloted aircraft (RPA) (1)

- Rugged computing glossary (1)

- SEDs (1)

- SIM Card (1)

- Secure boot (1)

- Sensor Open Systems Architecture (SOSA) (1)

- Small form-factor pluggable (SFP) (1)

- Smart Edge (1)

- Smart NIC (1)

- SmartNIC (1)

- Software-based CDS (1)

- Symmetric encryption (1)

- System hardening (1)

- System hardening best practices (1)

- TME (1)

- Tech Partners (1)

- Total Memory Encryption (TME) (1)

- Transfer CDS (1)

- USB ports (1)

- VMEbus International Trade Association (VITA) (1)

- Vertical Lift Consortium (VLC) (1)

- Virtual machines (1)

- What are embedded systems? (1)

- Wired access backhaul (1)

- Wireless access backhaul (1)

- accredidation (1)

- aerospace (1)

- air gaps (1)

- airborne computers (1)

- asteroid (1)

- authentication (1)

- autonomous (1)

- certification (1)

- cognitive software-defined radios (CDRS) (1)

- command and control (C2) (1)

- communications (1)

- cores (1)

- custom (1)

- customer service (1)

- customer support (1)

- data linking (1)

- data recording (1)

- ethernet (1)

- full disk encryption (1)

- hardware monitoring (1)

- heat sink (1)

- hypervisor (1)

- in-house technical support (1)

- input (1)

- integrated edge solution (1)

- international business (1)

- licensed spectrum (1)

- liquid cooling (1)

- mCOTS (1)

- microelectronics (1)

- missile defense (1)

- mixed criticality (1)

- moving (1)

- multi-factor authentication (1)

- network slicing (1)

- neural networks (1)

- new headquarters (1)

- next generation interceptor (1)

- non-volatile memory (1)

- operating system (1)

- output (1)

- outsourced technical support (1)

- post-boot (1)

- pre-boot (1)

- private networks (1)

- public networks (1)

- radio access network (RAN) (1)

- reconnaissance (1)

- rugged memory (1)

- secure flash (1)

- security (1)

- self-encrypting drives (SEDs) (1)

- sff (1)

- software (1)

- software-defined radios (SDRs) (1)

- speeds and feeds (1)

- standalone (1)

- storage (1)

- systems (1)

- tactical wide area networks (1)

- technical support (1)

- technology (1)

- third-party motherboards (1)

- troposcatter communication (1)

- unlicensed spectrum (1)

- volatile memory (1)

- vpx (1)

- zero trust network (1)

- January 2025 (1)

- November 2024 (1)

- October 2024 (1)

- August 2024 (1)

- July 2024 (1)

- May 2024 (1)

- April 2024 (3)

- February 2024 (1)

- November 2023 (1)

- October 2023 (1)

- July 2023 (1)

- June 2023 (3)

- May 2023 (7)

- April 2023 (5)

- March 2023 (7)

- December 2022 (2)

- November 2022 (6)

- October 2022 (7)

- September 2022 (8)

- August 2022 (3)

- July 2022 (4)

- June 2022 (13)

- May 2022 (10)

- April 2022 (4)

- March 2022 (11)

- February 2022 (4)

- January 2022 (4)

- December 2021 (1)

- November 2021 (4)

- September 2021 (2)

- August 2021 (1)

- July 2021 (2)

- June 2021 (3)

- May 2021 (4)

- April 2021 (3)

- March 2021 (3)

- February 2021 (8)

- January 2021 (4)

- December 2020 (5)

- November 2020 (5)

- October 2020 (4)

- September 2020 (4)

- August 2020 (6)

- July 2020 (9)

- June 2020 (11)

- May 2020 (13)

- April 2020 (8)

- February 2020 (1)

- January 2020 (1)

- October 2019 (1)

- August 2019 (2)

- July 2019 (2)

- March 2019 (1)

- January 2019 (2)

- December 2018 (1)

- November 2018 (2)

- October 2018 (5)

- September 2018 (3)

- July 2018 (1)

- April 2018 (2)

- March 2018 (1)

- February 2018 (9)

- January 2018 (27)

- December 2017 (1)

- November 2017 (2)

- October 2017 (3)

/Trenton%20Systems%20Circular%20Logo-3.png?width=50&height=50&name=Trenton%20Systems%20Circular%20Logo-3.png)

No Comments Yet

Let us know what you think